Maintenance systems for innovative manufacturers

Bridge ERP Quality offers a powerful method for tackling the root causes of expensive defects and guaranteeing quality throughout the entire product development process.

Facilitate automated upkeep procedures

to keep your connection alive.

Bridge ERP provides critical statistics to support your preventive maintenance planning, such as mean time between failures (MTBF), mean time to repair (MTTR), and the expected date of the next failure, while also facilitating the automation of metrology and preventive maintenance scheduling.

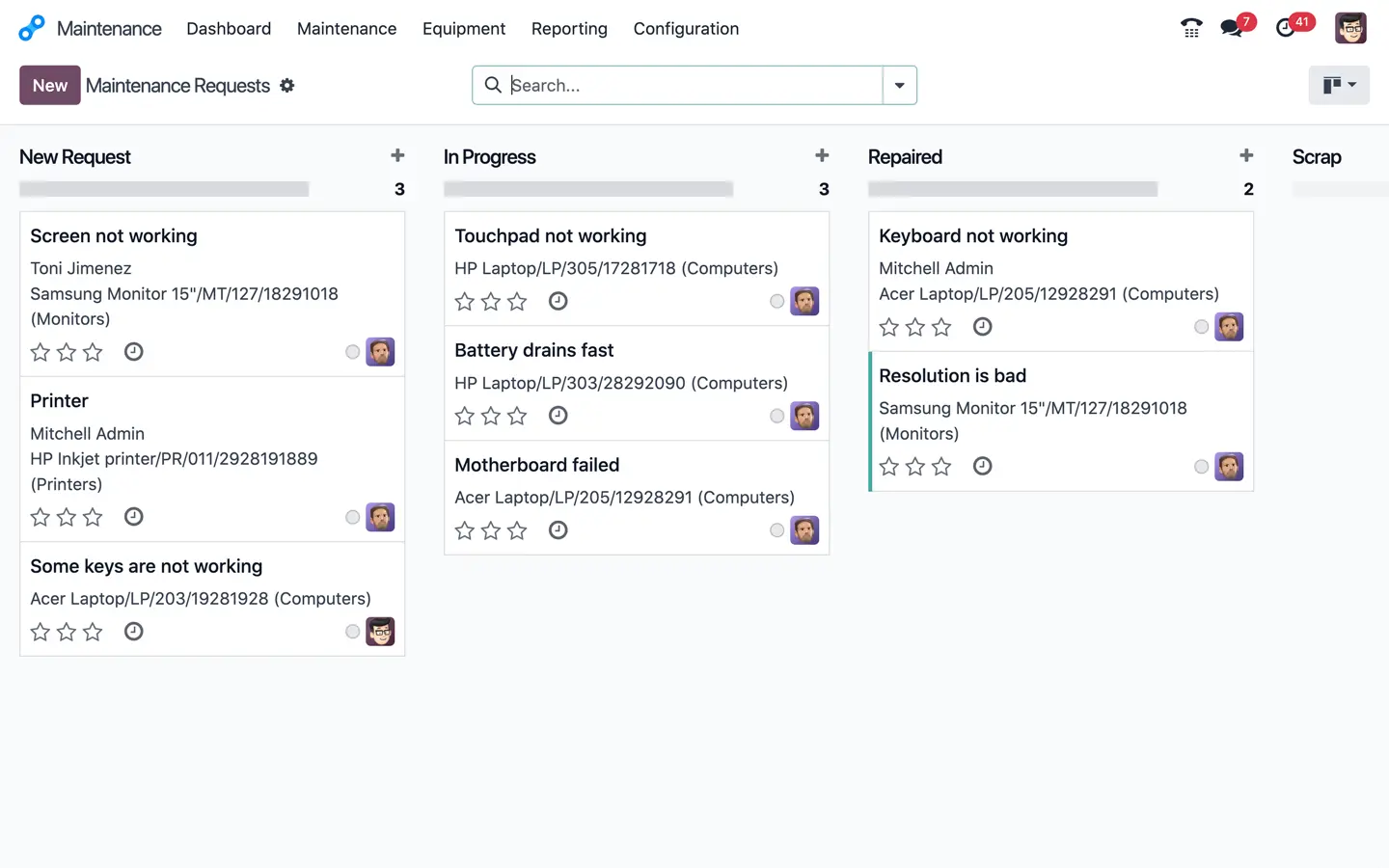

Coordinate your maintenance requests

offering fantastic kanban and calendar interfaces.

Conveniently monitor the development of maintenance requests using the kanban format. Take advantage of the maintenance calendar to effectively schedule and manage activities. Your team will appreciate the simple and efficient drag-and-drop system for handling maintenance requests.

Maximize equipment operational effectiveness

with streamlined maintenance.

From their work center control panel, the manufacturing department can easily initiate maintenance requests. As the maintenance team responds, the necessary personnel will be informed instantly.

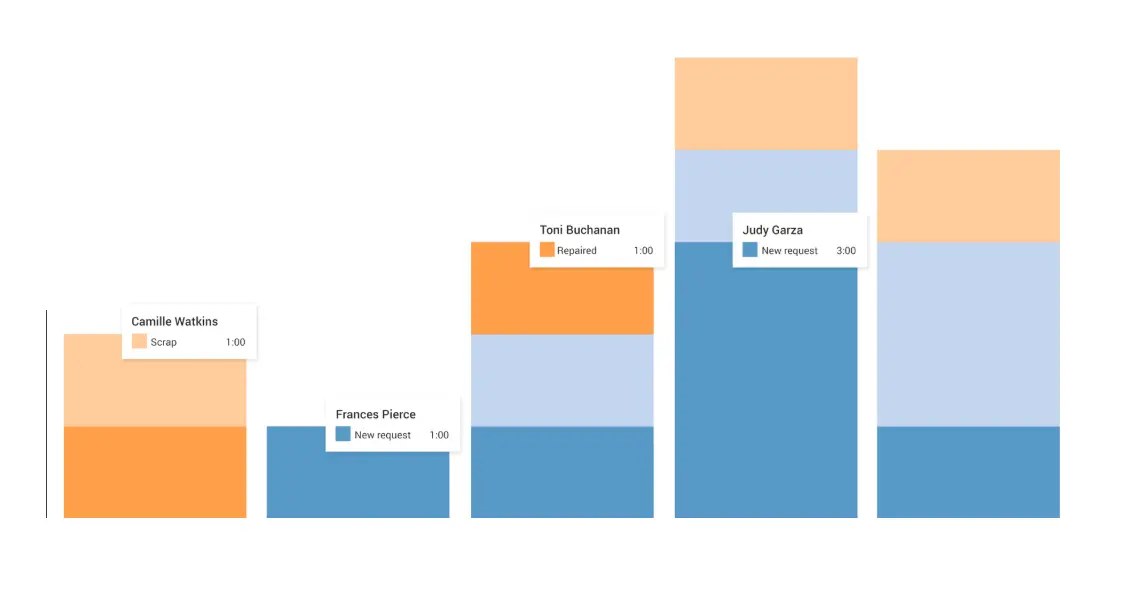

Dashboard & Statistics

to optimize your performance.

Use automatically computed statistics including MTBF and MTBR to fine tune your preventive maintenance rules and reduce the risk of equipment failure.

One goal, one tool.

Manufacturing

Manufacturing

The comprehensive workcenter control panel solution.

Quality

Quality

Define quality control points and trigger quality alerts easily

PLM

PLM

Manage engineering changes and versions easily